You are here

Resistance Welding

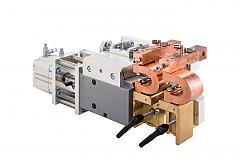

AMADA WELD TECH offers a wide range of welding technologies, including Linear DC, High Frequency Inverter, Capacitive Discharge and AC. We have over 100 years of experience in resistance welding which has enabled us to develop a versatile range that offers revolutionary designs for optimum and constant welding performance.

Our resistance welding equipment is used for resistance spot welding, seam welding, gap welding, projection welding, thermo-compression bonding, strand welding and insulated wire welding. AMADA WELD TECH offers resistance welding equipment and systems for all of these processes.

Products

Customized Solutions

Send your sample to one of our technology centers in Europe for an evaluation. We will then determine which solution meets your needs best. AMADA WELD TECH offers feasibility testing and application consulting.